The electric guitar born in the Engineering Technology Acoustics Lab at Purdue University during a String Instrument Fabrication course of the National STEM Guitar Project instructed by Dr. Mark French.

Design Stage

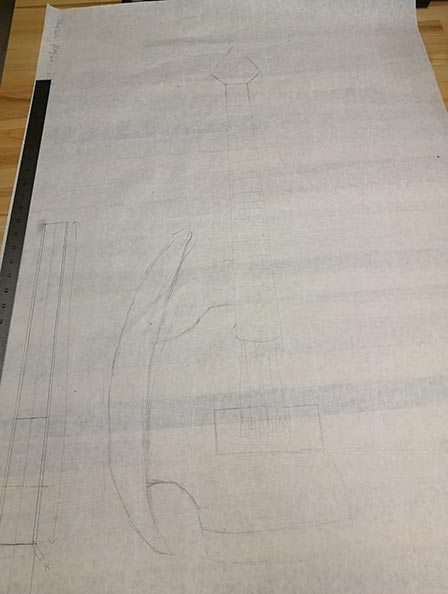

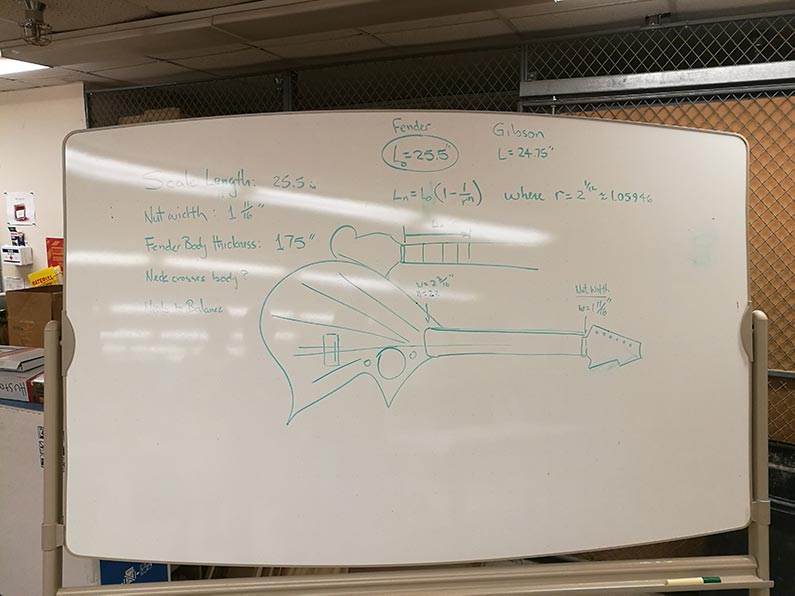

As the design concept of the guitar had been decided, we made lots of calculations to find the correct dimensions and sizes of functional guitar parts so that it can eventually work. As shown in the picture below, important dimensions like neck scale length and bridge position were calculated according to formulas. Also, body thickness was decided according to the actual thickness of the wood plank we had.

After that, we used lasercut cardboard to make prototypes of our design to have a more straightforward idea of it for us to optimize. Through several iterations, as one of it shown on the right, we had our final shape and dimensions decided.

After that, we used lasercut cardboard to make prototypes of our design to have a more straightforward idea of it for us to optimize. Through several iterations, as one of it shown on the right, we had our final shape and dimensions decided.

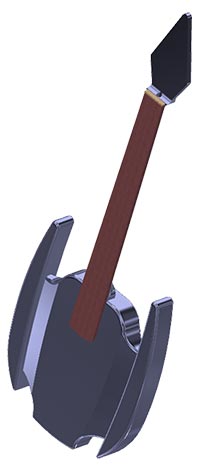

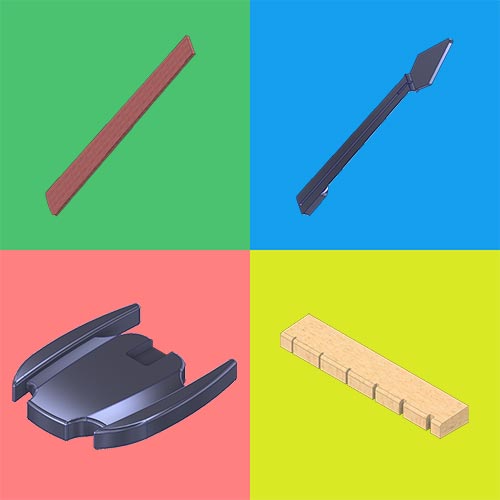

The final CAD model by using Autodesk Inventor Pro is finished as shown below:

Fabrication Stage

After the design stage, we used Inventor HSM(NOW Inventor CAM) CAM software to design CNC routing paths and generate the G-code compatible with our ShopBot CNC machine.

We used alignment pins and performed two sided machining to the wood block as shown in the picture below, and the result is shown on right.

We used alignment pins and performed two sided machining to the wood block as shown in the picture below, and the result is shown on right.

The neck was then cleaned up by removing the securing tabs, smoothing up the curved back-side, and inserting the truss rod, while the guitar body was CNC fabricated in a similar way to obtain the end result as shown below.

The guitar body was also cleaned, sealed, and painted. My guitar was black tinted in the picture below.

My fretboard was made from purple heart as shown on right, and cut with the automatic fret slotting machine made by our old fellow labmate.

My fretboard was made from purple heart as shown on right, and cut with the automatic fret slotting machine made by our old fellow labmate.

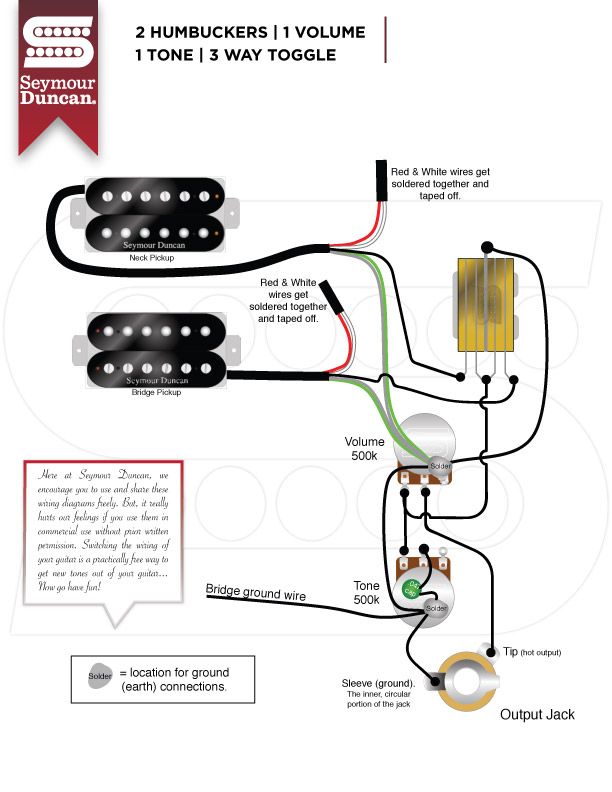

The parts were wired together according to the wiring diagram below by Seymour Duncan, and installed onto the guitar body.

Finally, everything was assembled together as shown on right.

Several prototypes were made from wasteboard during the processes introduced above, in order to verify and optimize designs as well as to practice our woodworking skills. As shown in the picture below, a broken neck can be found, which was used to test the neck strength by letting a human stand on it. As the result showed, it was broken and thus the design was optimized to come up with a thicker and stronger connection bridge to the head stock.

Several prototypes were made from wasteboard during the processes introduced above, in order to verify and optimize designs as well as to practice our woodworking skills. As shown in the picture below, a broken neck can be found, which was used to test the neck strength by letting a human stand on it. As the result showed, it was broken and thus the design was optimized to come up with a thicker and stronger connection bridge to the head stock.